Elevating Dairy Production: The Innovative Equipment by Ramal Mech Engg Pvt Ltd

In the dynamic world of dairy production, having reliable, efficient equipment is paramount. Ramal Mech Engg Pvt Ltd has established itself as a leader in manufacturing cutting-edge dairy equipment, catering to the diverse needs of dairy processors globally. From cheese vats to presses, their product line is designed to enhance productivity and ensure high-quality output.

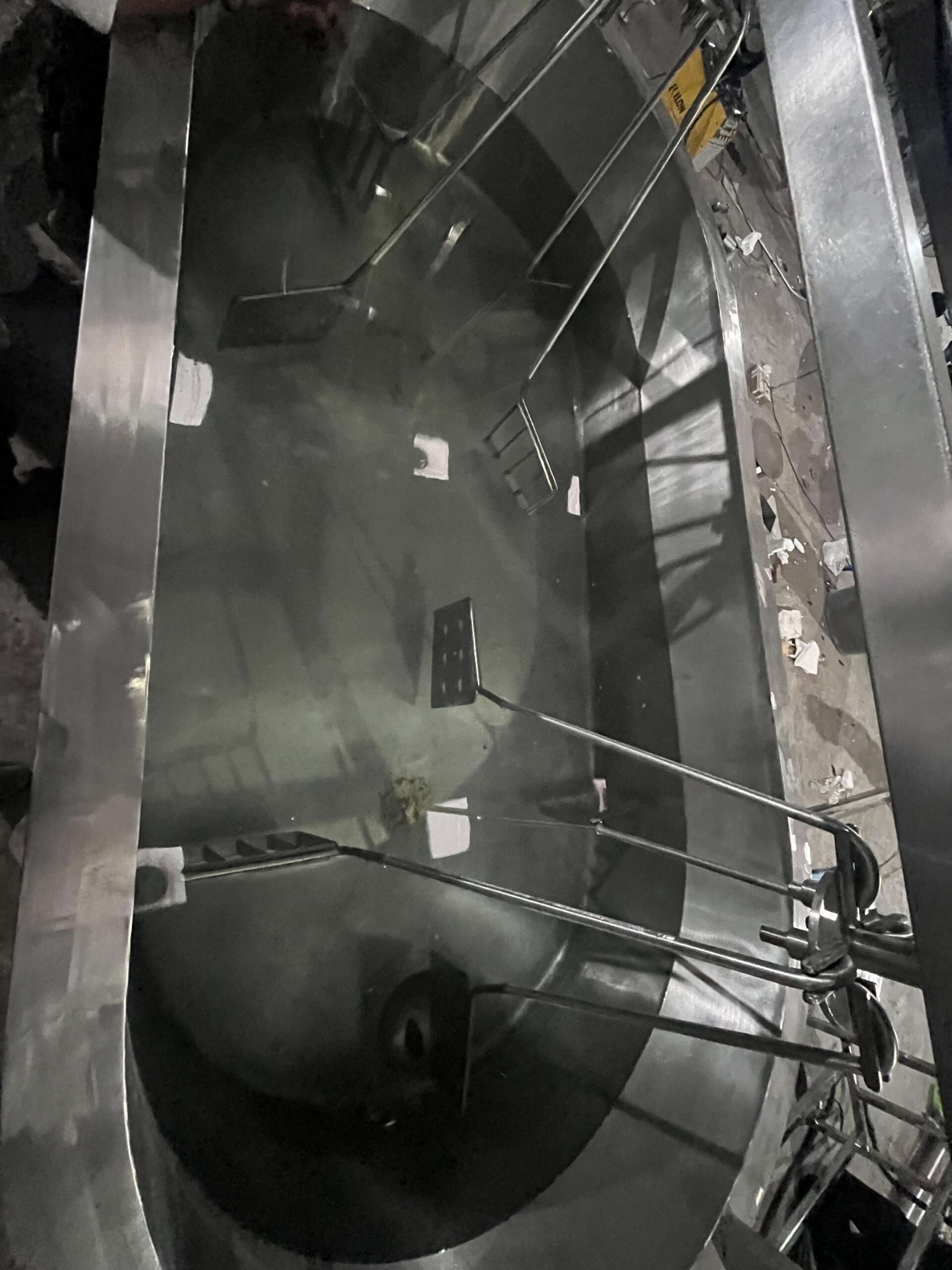

1. Cheese Vats: Precision and Quality

At the heart of cheese production is the cheese vat, and Ramal Mech Engg Pvt Ltd excels in this area. Their cheese vats feature advanced temperature control and agitation systems that ensure uniform heating and curd formation. Designed for scalability, these vats cater to both small artisanal producers and large-scale operations. The durable construction, often in stainless steel, meets stringent hygiene standards, making them a reliable choice for any dairy facility.

2. Cheese Presses: Perfecting Texture and Taste

The cheese press is crucial for achieving the desired texture and moisture content in cheese. Ramal’s cheese presses offer adjustable pressure settings, allowing producers to customize the pressing process for different cheese varieties. This flexibility, combined with a robust design, ensures that every batch meets the highest quality standards. Additionally, their easy-to-clean design supports efficient maintenance, making them a favorite among dairy processors.

3. Innovative Solutions for Every Need

Ramal Mech Engg Pvt Ltd understands that every dairy operation has unique requirements. Their team works closely with clients to develop customized solutions, ensuring that equipment perfectly aligns with production goals. Whether you’re looking for specific sizes, automation features, or enhanced energy efficiency, Ramal’s expertise can help tailor equipment to your needs.

4. Commitment to Quality and Safety

Quality and safety are non-negotiable in the dairy industry. Ramal Mech Engg Pvt Ltd adheres to international safety standards and employs rigorous quality control measures throughout the manufacturing process. This commitment ensures that every piece of equipment not only performs optimally but also contributes to a safe working environment.

5. Sustainability in Dairy Production

As the industry moves towards more sustainable practices, Ramal is at the forefront of this shift. Their equipment is designed to minimize energy consumption and reduce waste, helping dairy producers lower their environmental footprint while maintaining productivity.

Conclusion

With a focus on innovation, quality, and customer satisfaction, Ramal Mech Engg Pvt Ltd continues to set the standard in dairy equipment manufacturing. Whether you’re a small dairy producer or a large-scale operation, their range of products is designed to elevate your production processes, ensuring that you deliver the best dairy products to your customers. Explore the future of dairy production with Ramal Mech Engg Pvt Ltd—where tradition meets technology.

For more information on their products and services, whats app on +919811024797

Paneer press with multiple head and hoops , we have a range of paneer pressing machinery from single head , double head , triple head and quadruple head , till ten head . our hoop sizers can be made to get 5 kg to 30 kg of paneer in one press , pressure is 3 to 5 kg and its run by pneumatic